MS-96 Total Quality Management Sample Paper

MBA - Master of Business Administration

Note: Attempt any three questions from Section A. Section B is compulsory and carries 40 marks.

1. (a) Juran defined quality as fitness for use or purpose.' Critically evaluate the definition.

(b) A Writer on quality has proposed statement that quality is the only issue for organisational Survival. Discuss the statement in the light of the challenges facing contemporary organisations.

2. "Explain:

(i) Quality Function Deployment (QFD): and

(ii) Pareto analysis.

Illustrate your answer with suitable examples.

3. Draw up a typical structure for the promotion of TQM in a multi-divisional organisation. What roles to the steering committee and the TQM co-ordinators play?

4. Briefly discuss the core elements of an Environment Management System (EMS). How would you develop an EMS for an organisation?

5. What are the general requirements on the quality award process? List the key features of any one of the quality awards (National or international).

SECTION B

6. Read the following case study carefully and answer the questions given at the end.

Liberty Paint Works

ANANT SESHACHAR, THE 47-YEAR OLD CEO OF Liberty Paint Works (Liberty), took out a checklist from his pocket and simultaneously looked at his watch. It was 3.20 p.m. There were still 10 minutes to go for the meeting with Govardhan Patel, 43, executive director, Patel Consultants Inc… joining them would be Jagat Khurana, 42, Liberty's vice-president (operations) and the company's designated TQM coordinator. Having joined Liberty only three years ago as its CEO, Seshachar, who earlier headed the marketing operations of a transnational FMCG company's -- was still in the process of getting a grip on the company's business. The check-list contained brief notes on his conversations with Liberty's senior executives during the past few weeks.

TRILOK ROY, GENERAL MANAGER (MARKETING): "Until recently, most of my time was spent listening to customers, It was a great way of keeping in touch. I enjoyed it, but now, with cycle times being progressively shortened in the company, I find myself listening most of the time to subordinates."

LOPA MUDRA REGIONAL SALES MANAGER (WEST): "I met five key industrial customers in the western region during the past fortnight. I made a presentation to each on how we have cut down our delivery cycles as part of improving the quality of customer service. I pointed out how we now deliver in four weeks, instead of six, and that it is only appropriate that they should allocate a higher share of business to Liberty. After listening to me, all of them said that they would be reducing their order sizes. Is thus a precursor to our losing them to our competitions? Ask TQM."

SANTOSH CHATURAN, SALES COORDINATIO (EASTERN REGION): "In view of the declining time-cycles; the number of sales orders should have gone up. But, actually, they are coming down. As a result, I can't meet my annual targets which will affect my appraisal, due in March next. What is responsible? TQM."

MURUGAN SWAMINATHAN GENERAL MANAGER (PRODUCTION): "We have, no doubt, made progress in reducing out time cycle ever since we started implementing TQM. Labour Productivity has gone up by 20 per cent and machine productivity by 15 per cent. Considering that our direct labour cost is 8 per cent and depreciation id 7 per cent, respectively, of our sales, we should see an overall gain of 3 per cent in sales this year. But what we gain in the swings, we lose in the roundabouts. Since order bookings are down by nearly 30 per cent, we will have no close a shift and lay off people. Under utilisation of capacity will only add to rising costs, Reason? TQM."

ANIL SUD, GENERAL MANAGER (MATERIALS): "With a reduction in cycle times, we have to place purchase indents only seven weeks in advance as compared to 12 weeks earlier. But our suppliers insist on the earlier lead times since their internal planning is pegged to a 12 weeks cycle. I located alternative suppliers for binders and additives who fit in with our revised cycle times. But they are all based in the North. Our procurement costs will go up. Reason? TQM."

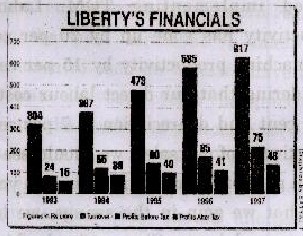

Liberty had been manufacturing and marketing for the last three decades. It led the decorative paints market with a 35 per cent marketshare in 1996-97, and was among the front-rankers in the industrial paints market with a 14 per cent marketshare. Its state-of-the-art manufacturing facilities at Hosur, near Chennai, were running at an 80 per cent capacity utilisation level. It was among the few paint companies to integrate backwards fully to manufacturer even titanium dioxide a key input which was in short supply and imported by most companies. Two years ago, Liberty --- then headed by Rajeshwar Mangal -- had commissioned Patel Consultants to implement a TQM programme. The decision had been triggered off by several factors. First, the industry structure was changing. The demand for decorative paints --- once taxed heavily by the government in the mistaken belief that paints were luxury items - was picking up because of a progressive reduction in the excise duties, And the entry of global players in the automobile and white goods sectors had spurred the demand for industrial paints.

Even as the industry was becoming competitive, there was an urgent need to improve quality, cut costs, and move closer to the customer. "TQM is only just beginning to deliver although there are a number of Grey areas," Mangal had told Seshachar before leaving Liberty in early 1997, to take up a job in Nigeria. The two had known each other for quite some time. :I believe in TQM," said Seshachar. "But I also believe in doing it my way," he added politely. As the meeting began, Seshachar set the tone by saying. "Before we get into details, let me tell you my own understanding of TQM, and what it means when implemented. To me, it means one of three trends. First, it could be a case of things getting worse before, they begin to get better. I have seen this happen with TQM in some companies. There is no need for concern here, All you need to do is to monitor the various indicated closely."

"Second, it could be a case of relapse. This again is common in companies undergoing change. But, it means trouble. Unless we move in quickly now, all the good work done will come instruct. And, third, there could be flaws in the way TQM is being implemented at Liberty. In which case, we need to go back to the basic and get our mornings right." "Your analysis -- and the areas of concern that you have raised --- just about sum up the roadblocks in implementing TQM." Said Patel. "It is, however, likely that the three trends could be happening simultaneously at different levels. Incidentally, all the problems relate to the concept of Total Cycle Time (TCT), which is under implementation."

"TCT, as it is called, "intervened Khurana, "is only a part of TQM. It would help if you get a part of TQM. It would help if you get a background of how it all started, and look at these problems in their right context, Goverdhan, why don't you begin at the beginning?" "TCT is defined broadly as the time taken from the expression of a customer need until the need is satisfied," said Patel, "Within that period, of course, lie thousands of activities each with its own time cycle. When you look at TCT as part of a TQM movement, you start examining each one of those cycles in detail. In the process, you would recognize numerous obstacles to productivity, which you never thought existed. "Once you eliminate these snags, the time cycle of that activity is shortened. And when a reduction in time cycle pervades every single activity, and becomes an integral part of your operations on a regular basis, you can respond to customer needs faster than competitors. That becomes a formidable weapon in the corporate arsenal. Business then becomes a seamless process instead of series of disjointed functions."

"Response time is a critical element of competitiveness for any business," said Seshachar, "but perhaps it is more so far a paints business."

"Yes," said Khurana. "As you know, the paints business is working capital-intensive. Net working capital represents over 50 per cent of the funds employed. The main reason is that we produce a number of shades in a variety of colour. This blocks a large part of our money. It must, however, be said that technology has been of great help here during the last few years."

"Instead of a standard shade-card, as in the old days, a computer screen provides a master palette containing over 500 shades, and you can actually see how the paint looks on the wall before deciding to buy it. Today, a customer can have any colour, any shade of his choice, on the spot. The desired shade is arrived at by mixing a base colour shade is arrived at by mixing a base colour -- usually, white-with appropriate stainers in an automatic machine. This automatically eliminates the need to stock pre-mixed colour shades with the dealers which, in any case, may not get sold. All one needs to do is maintain a stock of only the basic colour. While this cuts inventory-carrying costs, the problem of high working capital remains since one has to stock a vast range of pigments to produce a shade required by the customer."

"Beside, the manufacture of paints involves around 500 different types of raw materials contributing to 55 percent of the cost of sales. It is thus common to see 25 per cent of the sales blocked in raw material inventories alone. Moreover, we sell our decorative paints brands through 13,000 dealers who need to stock over 150 shades. As a result the speed of delivery and precision of product-mix are central to our commercial success. That's what makes the concept of TCT critical to our operations."

"Fine, How did you go about it?" asked Seshachar.

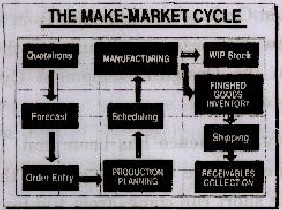

"We carved up operations ar Liberty into three broad time cycles: the Make-Market Cycle, Design-Development Cycle, and Strategic Thrust Cycle. The Make-Market Cycle covers the complete operating business cycle from the time a customer request a quotation until the receivables are collected. It has several sub-cycles like customer service and cash-flow, each with its own numerous mini-cycles such as order entry, forecasting, manufacturing, purchasing, warehousing shipping." The Design-development Cycle covers the entire process of developing new combinations of paints -- from identifying the market needs to the realisation of cost - effective production, And the Strategic Thrust Cycle covers activities from sighting a new business opportunity to the stage when the Design Development cycle can take over.

"My experience has been that, in most businesses, the biggest bang for the buck on the short run comes from tightening the Make-Market cycle. That is where the impact is immediate, and dramatic. In fact, bringing the Make-Market Cycle under control is a prerequisite to acting upon the other two. I may mention that although we started focusing on TCT in early - 1996, we are still on the Make-Market Cycle at Liberty. And the impact is just beginning to be felt. But the real impact on corporate results will be felt only when we complete all the three cycles. We are talking here of a five-year span." "That, in my view, is fairly long." Said Seshachar." We need to cut that cycle first. So, what happened, next?"

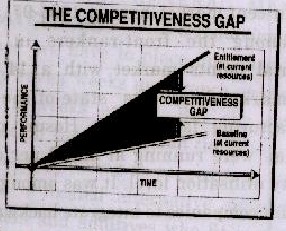

"Once we identified the sub-cycles and the mini-cycles in the Make-Market Cycle," continued Patel, "We established the time theoretically required for the completion of all the stages of a task in each mini-cycle. This we called a baseline. We already had data on most of the baseline in our Time and Motion Studies manuals. Once we had a grip on the thousands of baselines in a company, we established a new benchmark for each baseline after eliminating the redundant steps in the cycle." "The revised measure was called Entitlement. The gap between the two measures was called the Competitiveness Gap. People had to make the shift from the Baseline to Entitlement without seeking extra resources. In a year or two, this will become yet another parameter of performance appraisal."

"I can see why everybody is experiencing discomfort, as Trilok Roy told me during my meeting with him, even as we are halfway through TCT," said Seshachar looking at the check-list once again. "The brunt of the problem is being faced by Sud, I am sure," he went on/ "His fears of material costs going up are well-founded. Evidently, it is only when our suppliers also adopt TQM practices that the quality loop will be complete. Should we take the initiative in that direction? Indeed, why not? I also find this bit about shop-floor fears interesting. It must be handled carefully. People must know that security lies not in inventory but in competitiveness."

Questions:

(i) The management of Liberty funds that TQM has become is disenchanted with quality movement and even loyal customers are shifting away. How should Seshachar ensure that quality movement remains on course? Is the situation a cause for alarm?

(ii) How should the management of Liberty deal with the apprehension expressed by employees our TQM? Support your answers with reasons.